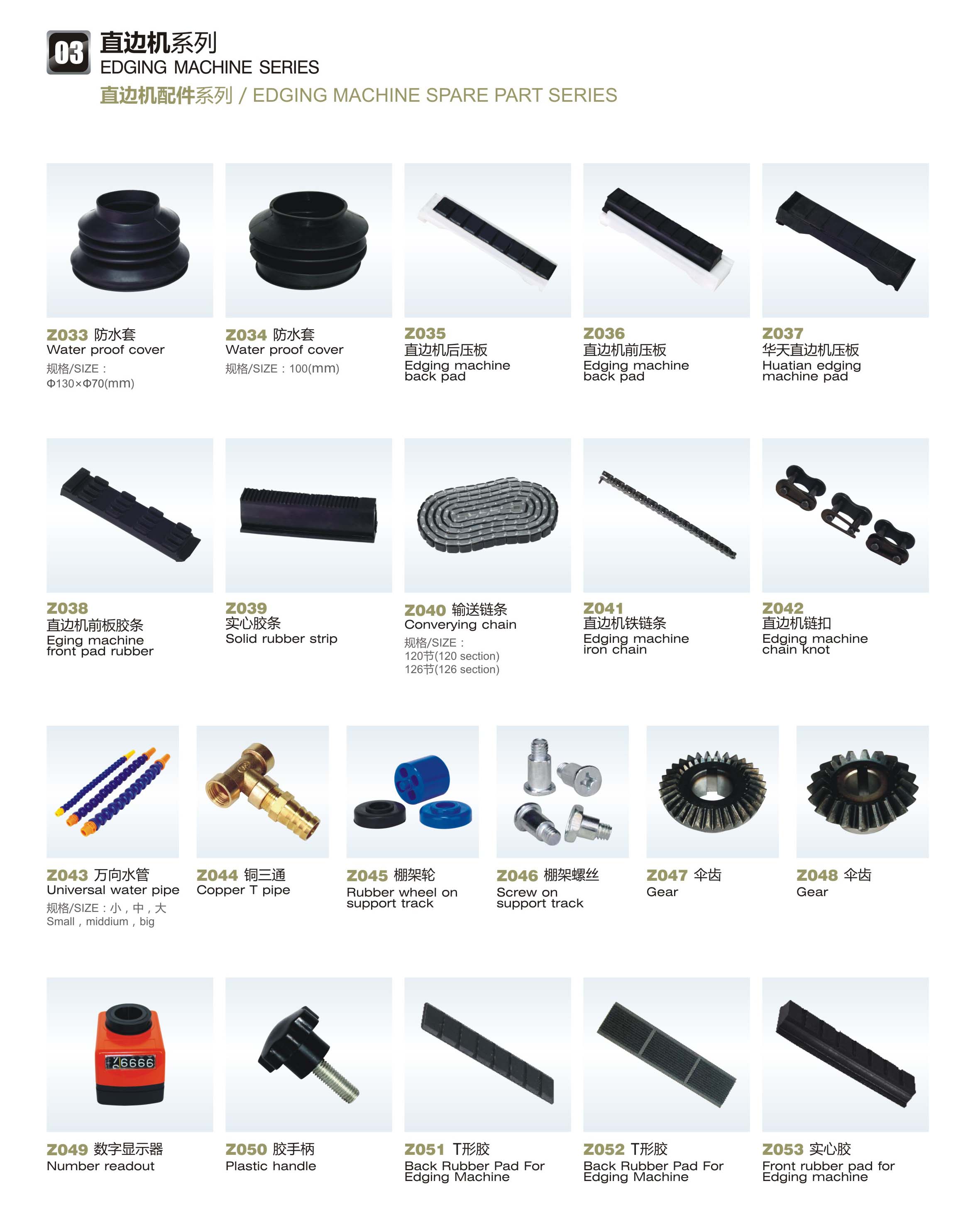

About accessories for Straight edge machine

Glass Straight Edge Machine is a kind of mechanical equipment specially used for processing the edge of flat glass, which is mainly used for fine grinding and polishing the bottom edge and corners of the glass, in order to improve the aesthetics and safety of glass products. This kind of equipment is widely used in construction, automobile, furniture manufacturing and other industries, and is one of the indispensable tools for deep processing of glass.

Features of glass straight edge machine

High-precision processing: the glass straight edge machine is able to grind and polish the glass edges accurately, ensuring smooth and burr-free edges.

Versatility: not only can it process straight edges, but it can also adjust the processing angle according to the needs, so as to achieve the processing of bevelled edges, rounded edges and other edge types.

Easy to operate: modern glass straight edge machine is usually equipped with intuitive control interface, which simplifies the operation process and improves the working efficiency.

High degree of automation: some high-end models are equipped with automatic feeding, size adjustment and other functions, reducing manual intervention and improving production efficiency.

Good stability: the use of high-quality materials and advanced manufacturing process ensures the stability and durability of the equipment under long-time operation.

Working principle of glass straight edge machine

Grinding straight edge: adjust the edge guiding plate, make the grinding wheel contact with the glass edge and keep the proper grinding amount, then start the machine, the grinding wheel grinds the glass edge with the help of coolant.

Grinding curved and rounded edges: no need to use the guide plate, the operator manually controls the mill to grind along the glass edge, and for rounded edges, it can be accurately processed by fixing the centre of the circle.

Adjustment of grinding volume: according to the processing requirements, the grinding volume can be adjusted quickly to suit different thicknesses and hardnesses of glass.

Operation steps of glass straight edge machine

Preparation: Check the status of the equipment, make sure all the parts are intact, and prepare the coolant.

Adjust the equipment: Adjust the position of the guide plate and grinding wheel according to the size and requirement of the glass to be processed.

Fixing the glass: Use the fixture to fix the glass on the equipment to ensure that it will not move during the processing.

Start the machine: switch on the coolant, start the grinding wheel and adjust the grinding speed as required.

Start processing: Manoeuvre the machine to grind along the set trajectory until processing is complete.

Clean up and maintain: After processing is completed, switch off the equipment, clean up any remaining glass fragments and coolant, and carry out the necessary maintenance on the equipment.

Maintenance and upkeep

Regular Inspection: Regularly check the wear and tear of the equipment, and replace the parts that are badly worn in time.

Lubrication and maintenance: Regularly lubricate the equipment to reduce wear and prolong service life.

Clean the worktable: clean the worktable after each use, keep the equipment clean and tidy.

Storage maintenance: when not in use for a long time, the equipment should be properly stored and maintained to avoid rust and damage.

Conclusion

As one of the important equipments for glass processing, glass straight edge machine has greatly improved the quality and productivity of glass products with its high efficiency and precise processing capability. With the continuous progress of technology, the future glass straight edge machine will be more intelligent and automated, bringing more possibilities for the glass manufacturing industry.

The following catalogue of accessories for straight edge machines is available: