About accessories for double edge machines

As the cornerstone of the modern glass processing industry, glass machinery is divided into various types according to different processing requirements and functional characteristics to meet various processing requirements from raw glass to finished glass products. Among them, the double-edged machine, as a member of the glass machinery family, is renowned for its efficient and precise edge processing capability, especially playing a key role in large glass production lines.

With its excellent ability to process both sides at the same time, the glass double edging machine greatly improves the productivity and product quality in the construction, automotive, furniture and other industries. The wide range of accessories not only ensures high performance and long service life, but also meets the specific needs of different processing scenarios. Below, we will take a closer look at the core components of the glass bi-lateral machine and their important role:

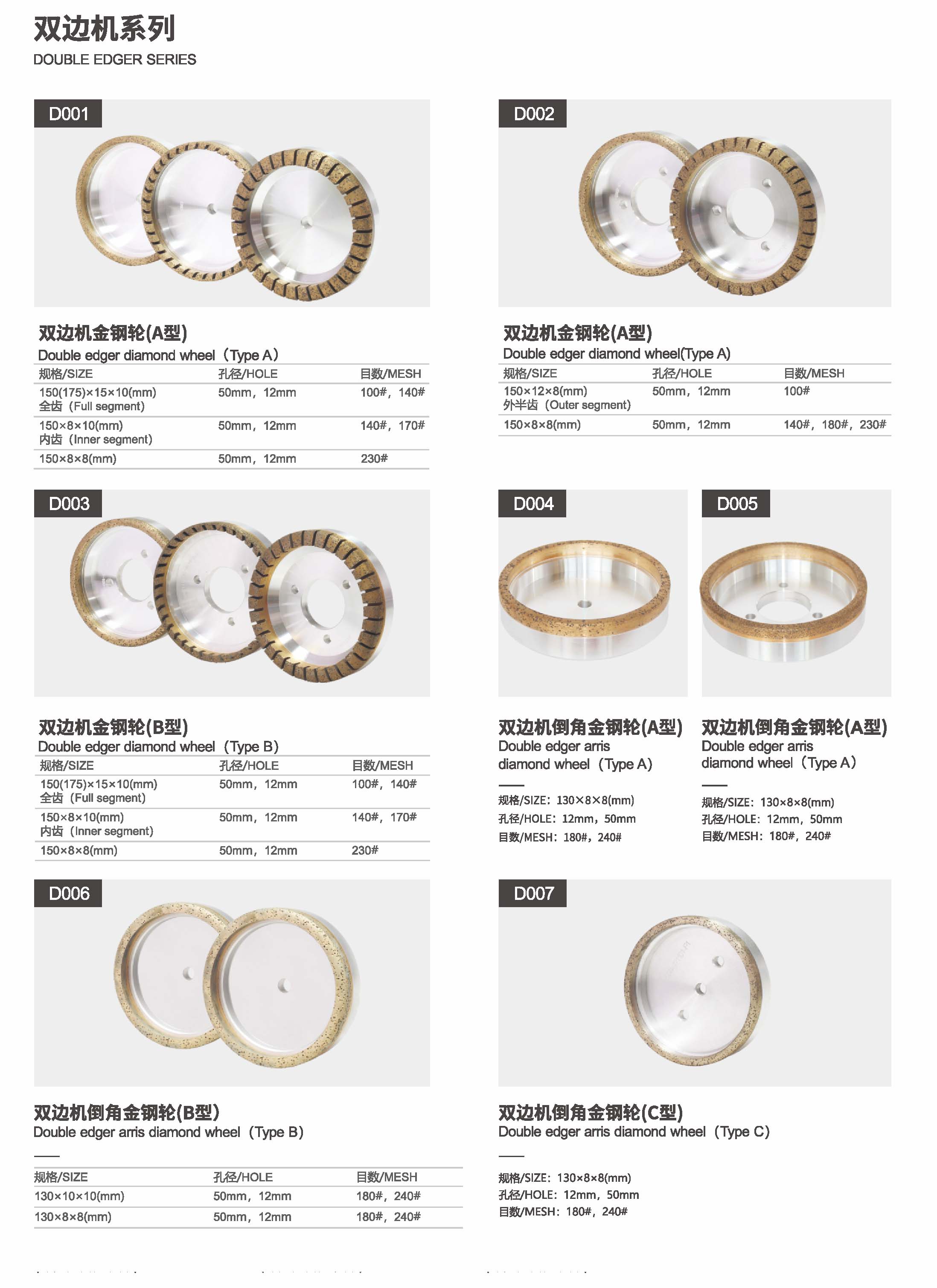

Grinding wheel and polishing wheel

Grinding wheel: Made of diamond or silicon carbide, it specializes in the rough grinding and semi-fine grinding of the glass edge, quickly eliminates edge burrs and irregularities, and paves the way for subsequent fine processing.

Polishing wheel: Made of wool, sponge or synthetic fiber materials, combined with polishing agents, it gives the glass edge a mirror-like delicate luster and improves its surface smoothness and beauty.

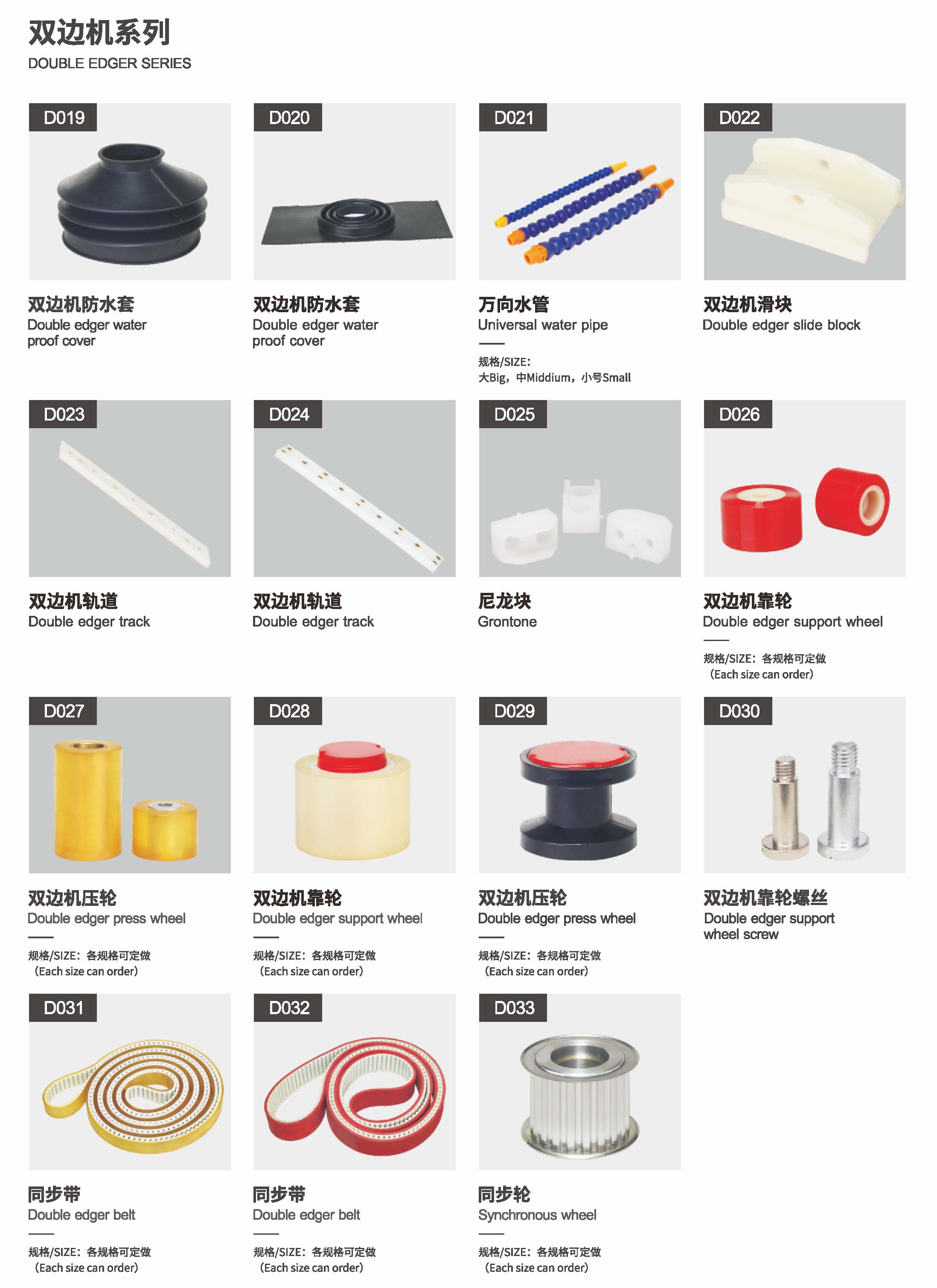

Cooling system accessories

Cooling pump: It is responsible for the delivery of coolant to ensure that the grinding wheel and polishing wheel are effectively cooled during operation, reduce thermal stress, and extend the life of the tool.

Coolant nozzle: Accurately control the flow direction and flow of coolant to ensure that the grinding area is fully covered, optimize the cooling effect, and improve processing accuracy and efficiency.

Transmission system accessories

Belts and chains: as the link of power transmission, they connect the motor and the working wheel to ensure smooth power conversion and distribution.

Gears and bearings: they bear the responsibility of support and guidance, reduce the friction between moving parts, and ensure the stable operation and high efficiency of the transmission system.

Control system accessories

Servo motors and drivers: realize precise speed and feed control, promote equipment automation and intelligent upgrades, and ensure the accuracy and efficiency of the processing process.

Sensors and encoders: monitor the operating status of the equipment in real time, collect key data such as position and speed, help the control system to respond immediately, and ensure the processing quality.

Clamping and positioning accessories

Vacuum suction cups: through strong vacuum adsorption, the glass is firmly fixed to ensure stability and accuracy during the processing process and improve the yield rate.

Guide rails and sliders: guide the precise movement of the glass, ensure the linearity and consistency of the processing path, and adapt to the processing needs of glass of various sizes and shapes.

Safety and maintenance accessories

Protective cover: covers the key parts of the equipment, effectively blocks the splashing of debris and the intrusion of dust, and protects the safety of operators and the cleanliness of the equipment.

Filter and dust removal system: collect dust and debris generated during processing, maintain a clean working environment, reduce health risks, and promote sustainable production.

A complete glass double sided machine accessories system is a solid foundation for the high performance and stability of the equipment. Regular inspection and renewal of worn accessories can not only significantly extend the service life of the equipment, but also continuously ensure processing quality and production safety. When purchasing accessories, it is strongly recommended to choose original manufacturers or certified suppliers to ensure the perfect fit and excellent quality of accessories, avoid equipment failures caused by non-standard or low-quality accessories, and effectively avoid production interruptions and economic losses. Through careful maintenance and scientific management, the glass double sided machine and its accessories will give full play to their potential and promote the glass processing industry to a higher level.

We have the following types of accessories: